This year’s early cold days have resulted in discomfort for many people, but not in this enterprise.

“We have a heat-insulated floor in our production facility, and we have also insulated the walls. Our employees can work in comfortable conditions even when the weather outside is freezing,” Bohdan Yemets, co-owner of the Kyiv Ventilation Plant, says contentedly.

The plant’s name features the word “Kyiv,” while the factory itself is located just near Kyiv, in Brovary. The plant is known for being the very first ventilation factory to be built from scratch in Ukraine. All others date back to Soviet times.

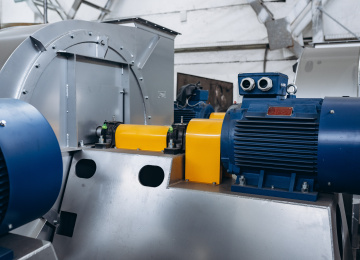

The plant produces industrial fans, some of them truly giant. People do not usually see or hear them, but these machines are providing good air quality in places where people work and spend their free time, like in factories, underground mines, water parks and shopping malls.

Transition from trading online to a modern plant

Bohdan started working with industrial fans in 2009, just after making an acquaintance with his future wife. She was working in the back office, while he worked in online sales.

“We came up with an idea to add a new section – industrial ventilation. Back then, no one imagined it was possible to sell complex industrial items online. It seemed like an interesting idea, and it worked out really well,” Bohdan tells the story of setting up his company, Industrial Fans, LLC.

When working as a distributor for another fan manufacturing plant, the company was selling up to 70% of their products. It had the biggest fan warehouse in Ukraine and the biggest specialty online store in the Commonwealth of Independent States (CIS).

It only worked so well for a while, though. Upon noticing that Bohdan’s initiative was becoming very successful and demand was rising, the manufacturer decided to change the terms for the worse. This prompted Bohdan to set up his own factory.

The new plant was established in 2015 with an investment of $240,000. At first, the company rented a big garage, where its first fan was produced two months after setting up the necessary equipment. After a while, they rented another garage. Eventually, the company purchased land and constructed a new production facility that would become the present-day Kyiv Ventilation Plant. The enterprise started operating in the new factory in January 2021.

The plant’s design is quite compact, and the facility provides for the whole production cycle ranging from metal cutting to configuration and painting. The plant employs around 100 people. Future plans include the construction of an additional production facility, as well the division of the production process to produce big and small machines separately.

“Our fundamental approach is to purchase new hi-tech equipment,” Bohdan says, “However, we would need to get a loan for that, or to set up our own fund and save money little by little to invest in technologies.”

“Energy for business”

Getting loans is a tricky matter for small and medium enterprises in Ukraine.

“It is very hard to run a business without proper access to finance. First of all, you cannot handle large orders, but you also cannot purchase new equipment,” Bohdan explains, “Loans provide lifeblood for business. When you get an opportunity to get a one million euro loan – your horizons get expanded.”

The biggest issue for medium enterprises like the Kyiv Ventilation Plant is high levels of collateral requirement, which sometimes exceed the amount of the loan itself. At the same time, banks do not consider equipment or warehouses as valuable, liquid assets, which also hinders access to finance.

“Banks require pledging collateral in the form of assets. This poses a huge problem for businesses. What are we supposed to provide? Everything is in our projects, like it’s ‘ethereal’. And the banks require physical liquid collateral. This issue precludes the possibility of getting a loan from the very beginning,” Yemets laments.

However, success stories do happen.

In 2019, Kyiv Ventilation Plant fell into real difficulties – it supplied a big batch of products to a large metallurgical company, but problems reared up when it came time for payment.

“The contract called for 100% payment after delivery. Meanwhile, a severe crisis began unfolding in the metal industry. This company was on the verge of bankruptcy. Of course, we had reserves covering any unexpected events during one to two months. However, payments were delayed for eight months for one shipment and for a year and a half for another shipment,” Bohdan Yemets says.

The company was saved due to a 6.6 mln hryvnia line of credit from ProCredit Bank. This loan was a special one – the plant got access to finance under the Lending Programme for Corporate, Small and Medium Business Customers supported by the EU4Business Programme. Under this Initiative, the European Investment Bank jointly with its subsidiary European Investment Fund provided partial portfolio guarantees to the selected Ukrainian banks in order to enhance access to finance for local SMEs.

This programme is one of many various financial instruments providing support to Ukrainian small- and medium-sized enterprises (SMEs) by the European Union.

“Every time we get a funding request, our bank seeks the best solution for the client,” says Yuliia Zahorodniuk, a junior loan officer working with business customers at ProCredit Bank. “In that case, our client was a company that was developing fast and could not pledge their assets as collateral. Therefore, the best decision was to suggest that the Kyiv Ventilation Plant apply for this programme. ProCredit Bank was able to extend this loan to the company thanks to the EIB Group’s guarantee, and helped KVP resolve their issues. The company continues developing and demonstrating good results.”

Terms for loans provided under the EIB Group’s guarantee are matched with the capabilities of small and medium enterprises. The maximum loan amount is five mln euros, while recipient companies’ annual turnover and their total assets may not exceed 50 mln euros and 43 mln euros, respectively. Companies may have up to 250 employees. The loan features an attractive interest rate compared to regular loans. Last but not least, the guarantee mentioned above allows ProCredit Bank to reduce its standard collateral requirements.

“Support for SMEs is one of the EIB Group’s priorities because by funding them we are boosting economic growth, innovation and employment. This guarantee agreement with our long-standing partner ProCredit Bank helps to increase access to crucial long-term financing for SMEs in order to help them continue to develop new projects and generate growth,” the EIB representative says.

“The European Union actively supports private sector development in Ukraine. We are happy that thanks to our EU4Business initiative, and cooperation with our partners from the EIB Group, we can contribute to the development of enterprises such as the Kyiv Ventilation Plant. Supporting SMEs and enhancing their access to financing allows them to fulfil their full potential and boost economic growth in Ukraine, along with contributing to stronger economic ties between Ukraine and the EU,” Chloe Allio, Head of the Economic cooperation, energy, infrastructure and environment section at EU Delegation to Ukraine said.

It is perfectly possible to become competitive on the EU market

There are currently seven plants producing industrial ventilation items in Ukraine. Imported products are also actively entering the market, which means that competition in the industry is quite high.

KVP is betting on the quality and technological effectiveness of the products, which pays off well. In August 2021, the plant produced 430 industrial fans – a record for the company, and a great production performance in the sector.

KVP exports its products to fifteen countries around the world. KVP also exports its products to the European Union, even though initially it is not easy to penetrate that market. The company was the first one in the field to receive a certificate attesting compliance of its products with the EU standards.

“We are delighted to have an opportunity to serve the European Union,” says Bohdan, “this market is highly competitive, technologically advanced and demanding. Harmonizing our products with the relevant standards and directives of the European Union enabled us to be competitive in that market as well.”