Few enterprises in Ukraine have a history of over 100 years—particularly successful ones. Soviet-era plants generally go to wrack and ruin unless some investor decides to put serious money into a complete modernization. Brovary's Ardenz Boiler Equipment Plant had a stroke of luck when Roman Kazanko bought the factory from its previous owners 10 years ago. He got a business with huge debts, old equipment and unmotivated workers.

Nevertheless, the following year, the enterprise already yielded a profit, and today it has a turnover of over UAH 100 million per year. Ardenz recently acquired a new laser machine through OTP Leasing within the EU4Business-EBRD Credit Line. Kazanko plans to expand production and promote exports to other European countries.

If at first you don't succeed...

When Roman Kazanko and his partner decided to buy Ardenz, they had definite plans: negotiations with German investors were underway and, together with a purchase order to be fulfilled by the plant, would provide for 10 years of regular infusions of capital. However, in 2009, during the world financial crisis, Ardenz's foreign partners changed their minds and decided not to invest in Ukraine. When the plant was finally acquired in 2011, no one knew what to do without investments and orders.

"It was like a wet blanket,” recalls Roman Kazanko. “You count on one thing, take all these steps, and then suddenly they tell you that everything has changed. And you’ve already invested $1.5 million in the project...”

Kazanko’s partner suggested shutting down the plant. However, Roman Kazanko understood that if they did that, the enterprise would end up a pile of bricks. Instead, he bought out his partner and learned all about a type of production that was absolutely new to him.

“When I started managing the plant, it was more than a hundred years old,” says Kazanko. “For Ukraine, it was more bad than good, related less to an outstanding history, than to the state of things. Technically the plant was in poor condition, with debts of about UAH 5 million, and the average age of its workers was 72!—retirees who were not being paid any wages, but just kept going to work. Of course, they didn’t work: they drank tea, talked about life, as they were just bored sitting at home.”

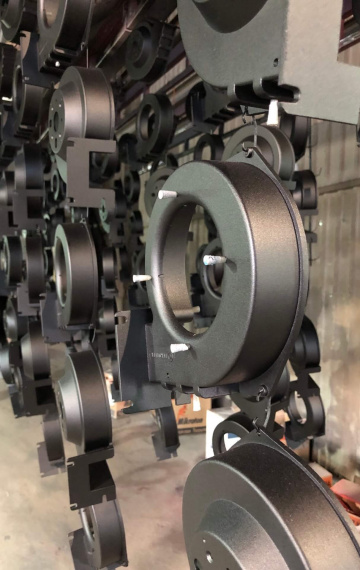

At that time, the plant could produce only expansion joints and outdated models of gas boilers. In the first year, Kazanko decided to sell them anyway, but despite good sales, he quickly realized that it was futile. At this point, Ardenz’s engineers began to develop high-end models and to produce about 15 new items per year. Gradually, the plant began to make huge thermal capacity boilers of about 50MW that were capable of heating entire cities.

Nowadays, Ardenz boilers are installed in every Ukrainian city with a population of more than 200,000. 2020 was a record year for the company, with a turnover of about UAH 100 million. This year, this is expected to increase by another 20%.

The roots of motivation

Prior to this, Kazanko had already owned a successful, proven business distributing cars. He also had a childhood dream of making Ukrainian cars. So he saw the opportunity to have his own metal processing plant as the first step to making his dream come true. He gradually was drawn into this. He says the best thing about this process is that you realize that everything actually depends on you.

"You make the right decision and the market reciprocates,” explains Kazanko. “When you are in a distribution business, where there are five to six chains, many decisions are not made by you, but they affect you.”

Today, Ardenz has around 80 employees and their production facility is already running out of space. Some items are even produced outdoors because there is no place for additional equipment indoors. At the moment, Kazanko is actively negotiating the construction of a new plant or the reconstruction of a suitable facility in Brovary.

The goal: €50 million in exports per year

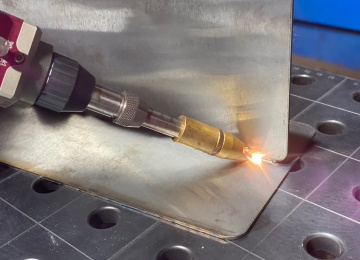

In November 2020, Roman Kazanko took out a loan via OTP Leasing, the EBRD's financial partner. He spent €300,000 on a new laser metal-cutter to replace the last old cutter. The laser cutter consumes less energy and significantly speeds up processes. This qualified the purchase fully for a EU4Business-EBRD Credit Line, which supports production upgrades and export potential.

“The 10% loan compensation provided by the European Union was a very significant support for us,” says Roman. “If not for this programme, we would not use leasing.”

Kazanko’s long-term goal for Ardenz is to increase exports to €50 million. It is quite ambitious for a business with a current export turnover of only €300,000-500,000 per year. However, the company has already set up a branch in Poland, and only the pandemic and closed borders hinder its expansion. There are plans to increase revenue with new production directions when the second plant opens. Kazanko does not say whether it will somehow be connected to car-making.

The Ukrainian businessman explains his success by the fact that, despite the serious level of competition in Ukraine, Ardenz wins when it comes to quality.

“Our economy is still being formed, so you can achieve success in any business sector, as long as you do your job, if not perfectly, then consistently well,” notes Kazanko. “Most of the problems are a reflection of the fact that the leaders are very one-sided. Some are good at manufacturing, but they don’t understand anything about commerce. Others are good business people, but can’t be bothered with the production side. If your approach to business is balanced, then you are bound to succeed."