Furniture surrounds us everywhere: at work, at home, in public spaces. A key part of comfort for humans, it’s impossible to imagine how uncomfortable life would be without such familiar things as tables, chairs, desks and beds. Today, the biggest problem is always choice. The selection is enormous, with options differing in size, design, decoration and, most importantly, material, the element whose qualities should be a priority criterion when choosing furniture.

"When the question is what furniture to buy, more and more often customers prefer Ukrainian manufacturers," says Mykola Viknyanskiy, owner of Termopal. “Our factories are now quite able to compete in quality with European ones. And the price, of course, is more attractive. The economic crisis allowed our factories to increase sales on the domestic market by 50% over the past two years.”

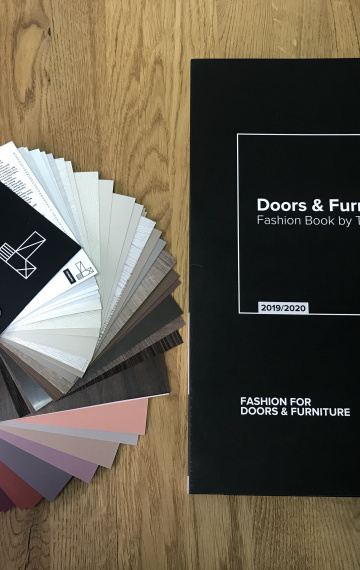

More than 20 years old, Termopal is Ukraine's largest supplier of materials for furniture production. Among other things, they import decorative paper and plastic, artificial stones and fittings.

“We are exclusive distributors of Impress, a German company that makes adhesive materials,” says Viknyanskiy. “We are also the only ones importing GRAAS fittings, from the Austrian company. In addition to European companies, we work with manufacturers from South Korea and Turkey.”

Changing technologies for European markets

More than 3,000 companies manufacture furniture in Ukraine today, both large companies with foreign investment and small local shops. Termopal works with about 35% of them.

Domestic furniture production is developing and gradually meeting international quality and design standards, making it extremely attractive for all players in this market. Indeed, the number of competitors is constantly growing.

The furniture industry began to take its current shape in 2015. Before that, more than 60% of exports went to Russian markets. At that point, Ukrainian manufacturers began to look for new opportunities and expanded their buyer markets. The approach to production technologies has also completely changed, which has positively affected the quality of goods on the domestic market.

"When we started to focus on western markets, we soon realized that our technologies were outdated by EU standards,” says Viknyanskiy. “It took a long time for distributors to adapt and furniture makers to meet EU standards.”

Today, domestic furniture makers are expanding exports to the EU and the Middle East. Poland is the #1 importer of Ukrainian furniture, with Germany in second place. However, these markets are mainly open to major market players, because they can afford the costly certification needed to enter EU markets. Small enterprises can’t afford it yet.

Difficult adaptation to new standards

Not only did furniture factories have to change and adjust to the new standards, but so did the companies that supply them with materials. Termopal received support from the EBRD through the EU4Business initiative to adapt the business to EU standards. In addition, 50 Termopal employees underwent a training program from some of the best managers and specialists in the domestic furniture industry. This allowed the company to optimize internal processes and make its operations more efficient.

“Our accounting system wasn’t very effective,” admits Viknyanskiy. “It was built around the product, not the customer—and this makes a big difference. We had to change that. We also fundamentally changed our approach to problem-solving. Now, with the help of the business seminars, my staff are thinking outside the box and are able to come up with several options for solving a problem.”

Through the employee training program, Viknyanskiy was able to introduce the Institute of HR Management at the company and this made the firm's work more predictable. The result was a 10% reduction in Termopal`s expenses.

Termopal continues to expand its list of potential international partners and buys high-quality materials for sale on the Ukrainian B2B market. Mykola Viknyanskiy has also decided to run another training program under the EU4Business umbrella for his employees because they themselves asked him for it.