Industrial companies are among the biggest polluters of the environment, and therefore they — more than any other business — require modern clean technologies. This story is about Ukrainian businesses whose developments help to reduce the carbon footprint in metallurgy. One of them, the Symvol company, replaces bronze with ferrous scrap metal in the production of sliding bearings, thereby making a product of higher quality. While the team of Chervona Hvilya enterprise designed a unique three-dimensional printing machine that uses ultra-durable material — titanium, — which is widely-applied in the aircraft and spacecraft industries.

Metal is among the most frequently used materials nowadays. Our world is built of metal: from cars and equipment to contemporary buildings. From a spoon for eating cereal to a wire connecting our house to the Internet — they are all made of metal. Ukraine is among the countries with expertise in high-technology metallurgical processes and full-cycle production of titanium and titanium-containing products. Ukrainian metallurgical enterprises are primarily concentrated around big cities, such as Donetsk, Zaporizhzhia, Dnipro, Kryvyi Rih, and Mariupol. With the beginning of the Russian-Ukrainian war in 2014, some enterprises from the East of Ukraine were forced to relocate to Ukrainian controlled territory.

Metallurgical giants, however, pollute the environment considerably, emitting billions of tonnes of carbon dioxide (CO2) into the air. The production of cast iron and steel, aluminium and titanium, copper and bronze is not without harmful emissions. Nowadays, global metallurgy and metalworking are seeking ways to decrease the levels of pollution, and solutions that would help to reduce the amounts of waste and utilise it as raw materials for manufacturing other goods. And this is where the new technologies step in.

Symvol. Making bearings out of scrap

The metallurgical company Symvol, meaning “symbol” in Ukrainian, casts technical components from various metal alloys, and produces sliding bearings, which are used in the mining, metallurgy, mechanical engineering, energy, and other industries.

Sliding bearings are an important part of many mechanisms that operate under heavy loads and in aggressive environments, where compactness and durability are required. When compared with better known rolling bearings (of which curious Ukrainian kids used to take the balls out), sliding bearings have a much simpler structure and better resistance to shock and vibration. Such bearings are made, particularly, of hard alloys like bronze, composite materials (containing plastic) and even of hardwood. However, according to Dmytro Akishyn, the director of Symvol, such bearings are quite expensive, and their production causes damage to the environment.

“We want to replace expensive materials with cheaper and more durable ones. These materials, named ACHM200 (АЧМ200, Antifriction Modified Cast-Iron — ed.), are the essence of our work.”

So how are the mechanical parts containing sliding bearings produced? An engineer designs a so-called “sliding pair”. Commonly, this is an axle and a bearing. The first thing is to build the bearing mould of expanded polystyrene, then, to build its wooden mould, and, finally, to cast a metal component, which still needs to be machined. Finally, the finished component is delivered to the customer.

The company Symvol developed an antifriction alloy that allows one to produce a sliding bearing from recycled material — ferrous scrap. Such a bearing, according to Dmytro Akishyn, serves longer than, for example, a bronze one, and also withstands higher pressures and temperatures.

Cast iron and steel, which compose 90% of the ACHM200 alloy, have outstanding antifriction qualities, when compared with bronze. This means that products made of such an alloy have a lower friction coefficient when interacting with other surfaces, which is a crucial factor in the production of bearings.

Symvol began its work in 2010 in the East of Ukraine, in Luhansk. But in just four years they had to stop all manufacturing because of the Russian occupation of the region. The company’s operations remained suspended for a year and a half.

“When we realised that the occupational administrations were about to cut our equipment up for scrap, we decided to evacuate it. I managed to rescue some of it. Back then, I didn’t know where we were moving to and how this all would work out. Over the phone, I was arranging the place to move all our stuff into and an industrial unit to rent. It was difficult: we had to have everything disassembled, loaded, with all the transport issues resolved. We also came under fire that time.”

By his own means Dmytro relocated some of the equipment along with the part of his team to Vinnytsa, and some time later the company moved to Chernihiv, where, according to Dmytro, they were offered a better deal to buy a site for the workshop. In 2015, the production was resumed.

“I relocated some of the employees from Luhansk, and we rented a hostel for them. We produced the simplest things, such as potbelly-stoves for the soldiers who didn’t have any heating at the time. Without proper laboratory equipment we couldn’t manufacture anything more complex. The first support we received from the EU was the job creation programme for displaced people; they also helped us buy modern laboratory equipment and reimbursed us half of its costs.”

Thus, the company started producing special antifriction alloys from scrap metal, resumed bearing manufacturing and signed contracts with partners from Hungary and Czech Republic. Also, Symvol keeps supporting scientific developments in Ukraine by cooperating with the Institute for Problems of Material Science NASU and their joint initiative — Research Institute for Materials and Alloys.

Dmytro says that they lack capacity to shift to mass production, and that is why their work so far is aimed at the domestic market — at the production of sliding bearings for Ukrainian companies.

In 2018, Symvol received a grant from the Climate Innovation Vouchers Programme, organised by the NGO Greencubator and with the assistance of the European Bank for Reconstruction and Development (EBRD). Thanks to the financial support, they certified their production and obtained European patents. Also, the company signed agreements with industrial partners from the EU. According to Dmytro, the company plans to attract investments to purchase the equipment for serial production.

“There are plenty of development opportunities in Ukraine: research centres, unique professionals, industrial facilities, and abundant resources. What is needed for development is attracting investments and getting effective equipment.”

The technology to produce bearings of scrap significantly reduces CO2 emissions into the atmosphere, when compared with the production of bearings from other alloys (0.7 kg of CO2 per 1 kg of raw material, which is five times less than the amount emitted during bearings production from bronze and 16 times less when using aluminium alloys).

For manufacturing the company utilises the scrap metal that is produced by Ukrainian enterprises. Symvol buys and recycles old products and equipment, thereby safely disposing of them.

“For example, we buy old rails from Ukrzaliznytsia (Ukrainian Railways — ed.) and melt them into new products. In Chernihiv there is a mechanical engineering enterprise that usually has some unused waste. We, as a foundry, buy that waste and manufacture mechanical components from it.”

Scrap metal is a raw material for foundry and metallurgical industry. Dmytro Akishyn says that Ukrainian companies simply cannot compete with Turkish or Chinese metallurgical enterprises in production volumes, because those two receive extensive state support. Ukrainian companies, with high costs of electricity and interest rates, do not have possibilities to gain a substantial share of the global market, Dmytro explains.

“A large amount of Ukrainian scrap metal is exported. For example, around 70% of these raw materials go to China. Turkey purchases the scrap from our country as well, and then exports the finished components back to Ukraine at prices our segment cannot compete with. We simply give out our raw materials, which could be recycled and used inside the country. We can only compete in the area of innovations.”

Sliding bearings of ferrous scrap serve four times longer than those of bronze. And they cost 70-80% less, as they save raw materials and energy.

“When making our alloy, we use scrap metal and a small amount of additives. For production of bronze, loads of substances that are harmful for the environment are used. If there is a large-scale object to be designed, like a hydroelectric power station, for example, the production time for this type of bearings could take up to a year. We can do this two to three times faster.”

Chervona Hvilya. Printing with metal

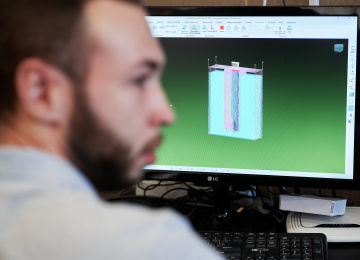

3D printing has been broadly used in light industry, design, architecture, medicine, construction, and other sectors for a long time. Using a 3D printer, we can create various parts and objects. To print a physical object, one needs to create its digital 3D model, either by computer modeling or scanning a real object with a 3D scanner. Such a model can be saved on a computer in a special format, and, when needed, be sent to print. Then, the 3D printer will process the file and start to reproduce the object: the printing part of the printer will apply the first layer of material, by melting or burning it with a laser (depending on a method of printing). Afterwards, the printer will continue to layer on the materials, one on top of the next, until a physical replica of the 3D model of the required size appears.

Ukrainian developers who work in metalworking applied the technology of 3D printing for making durable titanium components, which are used in the spacecraft and aircraft industries by a number of countries.

The team of the Chervona Hvilya company, Ukrainian for “red wave”, designed a unique machine that prints components using a titanium wire. The technology is called xBeam 3D Metal Printing, and, according to its developers, is cheaper, safer and faster than traditional methods of manufacturing titanium products, such as milling.

Also, according to a company’s co-founder Dmytro Kovalchuk, printing with molten wire and not with titanium powder (a widely-used method of 3D printing), is a technology that’s cheaper and easier to use.

Powder technologies for metal printing, as Dmytro believes, are now obsolete and primarily used in medicine. Such technologies are no longer widespread because of the high cost of the powder and, consequently, of the final products; and also because of a high percentage of waste from this mode of printing.

“Powders are very low-tech because of their extremely small particles. They are like dust and get spilled everywhere. To say more, the powder from active metals, such as titanium, poses a fire and an explosion hazard. That means, they require special safety measures, special facilities, special skills, and experience.”

Titanium was discovered back in the 18th century, but its broad usage only began in the second half of the 20th century. This metal is also called “volatile”, because of its strength, corrosion resistance and much lighter mass, when compared with other metals. Titanium is often used in production of “key components”, when weight and reliability of a product are critical: for example, in the manufacturing of components for airplanes, rockets, turbines, and race cars.

Chervona Hvilya has been working with titanium for more than 20 years. Founded in 1997, the company initially produced titanium ingots out of recycled scrap metal and supplied them to the global market. The use of recycled materials considerably cut the cost of traditionally high-priced titanium products without loss in quality.

“In Ukraine, there was plenty of scrap metal, because in the 90s, after the dissolution of the USSR, many enterprises were simply “scrapped”. Non-ferrous scrap metal was exported abroad virtually for nothing. But we, unlike those companies, familiarised ourselves with the needs of the titanium industry and had a technology of electron-beam melting, so we managed to develop a method of recycling the titanium scrap and making ingots from it.”

Dmytro Kovalchuk says that it is the team of Chervona Hvilya that conceived the idea of recycling almost all the scrap metal available. Back in 1996, having visited American titanium enterprises, Dmytro noticed that the materials that Ukraine used to sell can be melted into quality titanium ingots. Then, with the partners from Paton institute, they decided to try using scrap metal in the manufacturing.

“As a result, we entered the global market virtually in a year or two. At that time, we did it with fantastically cheap but quality production. Among our clients, there were companies from the USA, China, and Russia. At some point, we even started importing scrap into Ukraine. Because the scrap metal was exported from Ukraine indiscriminately, we had to buy it in Germany at a much higher price. But we managed to reverse those flows. We were increasing our production volumes and gradually became a notable player on the global market.”

Despite its wide occurrence in nature, titanium is still considered an exotic and expensive metal. It is resistant to high temperatures (the melting temperature of titanium is approximately 1,700°C). Machining (milling) of titanium ingots also requires significant resources and expensive equipment. In addition, titanium waste — swarf and scrap — are difficult to recycle, which is why the technologies with minimised production waste become an optimal solution.

“Titanium is a very interesting material. I have been working with titanium for more than 30 years already. It has a unique set of characteristics and properties. It is both stronger than many steels and almost two times lighter. That is, you can make the same component able to withstand the same load twice as light.”

Chervona Hvilya applied for a number of support programmes for innovative green solutions in manufacturing. The team received a grant from the programme Horizon 2020, and in 2018, funding of €50k as a part of the Climate Innovation Vouchers project organised by the NGO Greencubator and with the assistance of the European Bank of Reconstruction and Development (EBRD) and the European Union. The innovation voucher helped the company develop the software for automatisation of the printing process and its integration with the leading programs for engineering and design (CAD-systems). This decreased the number of printing errors, increased the output of quality components and improved the quality of their coatings, which, respectively, reduced the need in their finishing.

“We are working on resource conservation. And it is important for the whole world. For example, laser powder printing (laser sintering — ed.) is already in use in Ukraine. I know that in Odesa there is a company that developed the technology of printing with ceramics. If everything works out for them, that would be great, and Ukraine would get its own school of printing. This is why providing support for such ‘green’ projects is an example of common effort for common good.”

In 2019, the printing system of Chervona Hvilya was purchased by the British Welding Institute (TWI), a partner of British Aerospace.

“Currently we have three active contracts. One is with a UK customer, from Cambridge, and the other two — with Chinese clients. What they have in common is that they’re all related to the aerospace industry. They are the research organisations that work in the interests of the aerospace industry.”

хBeam 3D Metal Printing technology. The beginning

Dmytro Kovalchuk graduated from the Department of Aerophysics and Space Research of the Moscow Institute of Physics and Technology, which, in the Soviet times, cooperated with Paton Institute of Electric Welding of the National Academy of Sciences of Ukraine.

“We had a ‘visiting’ education system. For the first four years in Moscow, we studied general subjects, and after passing qualifying exams, for the fifth and sixth years, we moved to Kyiv, where we were appointed to certain departments of Paton Institute to take part in scientific research.”

At the end of the 1960s, a powerful scientific centre for the developing and manufacturing of electron-beam equipment started operating at the Kyiv Polytechnical University and Paton Institute of Electric Welding (the latter was where Dmytro stayed to work after graduation). The centre was manufacturing smelting ovens, welding machines and also electron beam guns, the ones Chervona Hvilya began producing components for in 2005.

Electron guns of a gas-discharge type were designed by Chervona Hvilya together with scientists of the Kyiv Polytechnic University. Such guns are used for pulsed deposition of multi-component and complex metal coatings. Today, these Ukrainian electron guns are used in the USA, China, Japan and countries of the European Union.

“As follows from its very name, an electron-beam gun is a device that, so to speak, shoots electrons. It is a device that forms an electron ray — a beam of electrons, which jets from the gun with immense speed. Their speed is accelerated by high voltage transmitted to the cathode (electrode of the device connected to the negative pole of a current source — ed.). A large amount of electrons, collected in the beam, carry a stupendous energy.”

A highly powerful electron gun, says Dmytro Kovalchuk, is able to melt up to 8-9 kg of titanium wire per hour.

The technologies that Chervona Hvilya had been using before 2014 were of dual-use. For instance, the manufactured components could be utilised for both civil and military aircrafts. Thus, some countries applied export restrictions on these technologies.

“The question is what hands [the equipment] will get into, who will use it and what for. For example, among our clients there was an American company that knew we were also supplying the equipment to Russia, so they had certain stipulations restricting our capacities at that time. As for 3D technologies, these are not dual-use, so it’s much simpler for us, without any restrictions.”

Since 2014, the company has focused on the development of its own three-dimensional printing technology to manufacture products from metal wire.

“One time, when I was visiting a customer of our electron guns in China, they demonstrated to me a 3D printing technology that they were developing based on our equipment, and asked whether the effectiveness of our guns could be applied to it. This is where we started our journey into 3D printing. Back then, six years ago, I was amazed that nearly no one was practising wire printing.”

And if by that time Dmytro already knew the Ukrainian market of metal melting and its supplies well enough, Chervona Hvilya had to start the work in the 3D printing market from scratch.

“Our initial investors were, obviously, our acquaintances. As is often the case, those were the ones who believed more in me than in the project itself. In fact, there was no project yet, no profit, no understanding of how we would be entering the market, because this was a new market for us — we were unknown. So our first funds raised were basically ‘friendly loans’.”

Today Chervona Hvilya produces three types of 3D titanium-printing systems. The first one is the “laboratory” system XBeamLab. It is a compact system that is intended primarily for conducting experiments at universities and for small-scale producers who manufacture small components.

Another system is XBeamWorks. It is of a medium size, its produced components can be conveniently taken out, passed on to the machine with a computerised management system for final processing, and received from the latter already finished.

Sometimes we need to print very large or unusually configured parts. XBeamGrand is the common name for all the non-standard, large equipment.

During the production of a titanium component by milling, from 60% to 90% of metal goes to waste. This method, for example, requires 20-30 kg of titanium to produce a component, while using xBeam 3D technology requires only 3-5 kg. If the manufacturing of 1 kg of titanium produces up to 35 kg of CO2 emissions, 3D printing reduces the levels of harmful emissions almost tenfold.

For printing, the developers of the 3D titanium printer use a metal wire, which is melted in the focal point of an electron beam under high temperature. So it’s the wire that the printer composes a required component from. The name of the technology xBeam stems from the shape of an electron beam, which resembles a letter “X”.

“The idea came as a diagram on a paper showing how to make a prototype, conduct the experiment, get our first X-beam and print the first component. It took us a bit less than a year to validate our assumptions and to make sure they worked.”

The very quality and precise control over the production processes are mentioned by the company as the unique features that distinguish them from all the other 3D printing technologies.

“Our technology is like squeezing out toothpaste on a toothbrush, when it spreads out easily, controllably and evenly on the surfaces you want. And this is our critical advantage over all the other 3D printing technologies. We add metal in a very controllable way, thereby regulating the structure and the quality of the metals. We also reduce the amount of waste that usually occurs as a result of further machining.”